Oversigt over specifikationer

-

Accuracy

+/- 2 mm (0.08 in)

-

Process temperature

XT: -196...+280 °C

(-321...+536 °F)

HT: -196...+450 °C

(-321...+842 °F) -

Process pressure / max. overpressure limit

Vacuum...160 bar

(Vacuum...2320 psi) -

Max. measurement distance

Standard: 40 m (131 ft)

With "Advanced dynamics": 70 m (230 ft) -

Main wetted parts

316L, Alloy C, PTFE, ceramic

Anvendelsesområde

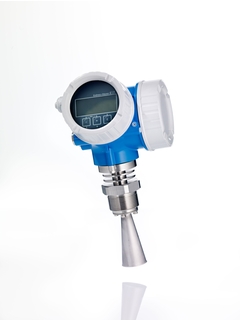

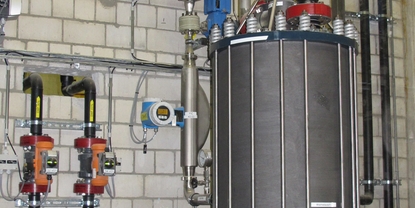

Micropilot FMR51 for level measurement even under extreme process conditions like high temperature and high pressure in the oil & gas and chemical industry. The FMR51 free space radar offers maximum reliability due to an innovative and patented sensor-design. Micropilot is used for continuous, non-contact level measurement of liquids, pastes and slurries. The measurement is not affected by changing media, temperature changes, gas blankets or vapors. Remote access via SmartBlue app is available.

Horn antenna for level measurement even under extreme conditions.

Process connections: Thread, Tri-Clamp or flange

Temperature: -196 to +450°C (-321 to + 842°F)

Pressure: -1 to +160bar (-14.5 to +2,320psi)

Maximum measuring range: 40m (131ft), 70m (230ft) for enhanced dynamics

Accuracy: ±2mm

K-band: 26GHz

International explosion protection certificates, overfill prevention WHG, SIL, marine approvals, 5-point linearity protocol

Remote access with SmartBlue App via Bluetooth® is available

Fordele

Hardware and software developed according to IEC 61508 up to SIL3 (in homogeneous redundancy)

HistoROM data management concept for fast and easy commissioning, maintenance and diagnostics

Highest reliability even in the presence of obstructions in the vessel due to new Multi-Echo Tracking evaluation

Heartbeat Technology for a cost-effective and safe plant operation during the entire life cycle

Seamless integration into control or asset management systems and intuitive, menu-guided operation concept (on-site or via the control system)

World's easiest proof test concept for SIL and WHG saves time and cost

Highest safety due to double ceramic coupling and gas-tight feedthrough

Videoer

-

Standardprodukter

- Pålidelige og robuste med lav vedligeholdelse

Teknisk ydeevne

Enkelhed

-

Specialiserede produkter

- Designet til krævende applikationer

Teknisk ydeevne

Enkelhed

Variabel

| FLEX valg | Teknisk ydeevne | Enkelhed |

|---|---|---|

Fundamental Få dækket dine basale målebehov |

Teknisk ydeevne

|

Enkelhed

|

Lean Administrer nemt dine kerneprocesser |

Teknisk ydeevne

|

Enkelhed

|

Extended Optimer dine processer med innovative teknologier |

Teknisk ydeevne

|

Enkelhed

|

Xpert Til de mest udfordrende applikationer |

Teknisk ydeevne

|

Enkelhed

Variabel |

Loading alternative products

Loading alternative products

Forgænger

-

-

Tekniske oplysninger (TI)

Micropilot FMR51, FMR52

Engelsk version - 07/2020

Free space radar

EN DA 24/07/202012/04/201801/09/201715/12/201628/04/2016Sprog:

Engelsk

Version:

24/07/2020

Filstørrelse:

3.8 MB

Filnavn:

TI01040FEN_1020.pdf

-

-

-

Ex-sikkerhedsanvisning (XA)

Micropilot FMR50/51/52/53/54/56/57

Engelsk version - 05/2022

4-20 mA HART Ex ia/db [ia Ga] IIC T6...T1 Ga/Gb Ex ta/tb IIIC T85°C Da/Db

EN DA 20/05/202225/06/201812/11/2013Sprog:

Engelsk

Version:

20/05/2022

Filstørrelse:

561.1 KB

Filnavn:

XA01206FEN_0322-00.pdf

-

-

-

Tekniske oplysninger (TI)

Micropilot FMR51, FMR52

Free space radar

EN DA 24/07/202012/04/201801/09/201715/12/201628/04/2016Sprog:

Engelsk

Version:

24/07/2020

Filstørrelse:

3.8 MB

Filnavn:

TI01040FEN_1020.pdf

-

-

-

Betjeningsvejledning (BA)

Micropilot FMR51, FMR52 HART Operating Instructions

Free space radar

EN DA 12/04/201821/09/201715/12/201628/04/201601/12/2014Sprog:

Engelsk

Version:

12/04/2018

Filstørrelse:

4.3 MB

Filnavn:

BA01049FEN_0718.pdf

-

-

-

Betjeningsvejledning (BA)

Micropilot FMR51, FMR52 PROFIBUS PA Operating Instructions

Free space radar

EN DA 12/04/201815/12/201601/12/201415/04/2013Sprog:

Engelsk

Version:

12/04/2018

Filstørrelse:

3.7 MB

Filnavn:

BA01125FEN_0418.pdf

-

-

-

Betjeningsvejledning (BA)

Micropilot FMR51, FMR52 FOUNDATION Fieldbus Operating Instructions

Freespace radar

EN DA 12/04/201815/12/201616/07/201501/07/2013Sprog:

Engelsk

Version:

12/04/2018

Filstørrelse:

4.8 MB

Filnavn:

BA01121FEN_0418.pdf

-

-

-

Enhedsparameter (GP)

Micropilot FMR50, FMR51, FMR52, FMR53, FMR54, FMR56, FMR57 PROFIBUS PA Description of Device Parameters

Free space radar

EN DA 30/10/201415/04/2013Sprog:

Engelsk

Version:

30/10/2014

Filstørrelse:

3.9 MB

Filnavn:

GP01018FEN_0214.pdf

-

-

-

Enhedsparameter (GP)

Micropilot FMR50, FMR51, FMR52, FMR53, FMR54, FMR56, FMR57 FOUNDATION Fieldbus Description of Device Parameters

Free space radar

EN DA 16/07/201501/07/2013Sprog:

Engelsk

Version:

16/07/2015

Filstørrelse:

2.8 MB

Filnavn:

GP01017FEN_0215.pdf

-

-

-

Enhedsparameter (GP)

Micropilot FMR5x HART Description of Device Parameters

Free space radar

EN DA 28/04/201630/10/201415/04/201330/01/201314/12/2012Sprog:

Engelsk

Version:

28/04/2016

Filstørrelse:

2.5 MB

Filnavn:

GP01014FEN_0516.pdf

-

-

-

Kort anvisning (KA)

Micropilot FMR51, FMR52 PROFIBUS PA

Fritrumsradar

EN DA 01/08/202212/04/201802/02/201515/04/2013Sprog:

Dansk

Version:

01/08/2022

Filstørrelse:

1.3 MB

Filnavn:

KA01129FDA_0422-00.pdf

-

-

-

Kort anvisning (KA)

Micropilot FMR51, FMR52 HART

Fritrumsradar

EN DA 01/08/202212/04/201822/09/201712/02/201515/04/2013Sprog:

Dansk

Version:

01/08/2022

Filstørrelse:

1.5 MB

Filnavn:

KA01100FDA_0622-00.pdf

-

-

-

Kort anvisning (KA)

Micropilot FMR51, FMR52 FOUNDATION Fieldbus

Fritrumsradar

EN DA 01/08/202212/04/201801/07/2013Sprog:

Dansk

Version:

01/08/2022

Filstørrelse:

1.3 MB

Filnavn:

KA01125FDA_0322-00.pdf

-